In solar pumping system applications, it’s common that the distance between solar pumping inverter and water pump is over 200 meters. It may due to the project’s total lift head is over 200 meters, or the space limitation for simplified management .

Long pump cable has high distributed capacitance to the earth, in such condition, the solar pumping inverter’s high frequency PWM output voltage will charge the output capacitance, which will result in high frequency pulse overvoltage. The overvoltage may damage the motor by breaking down the winding.

With years of operation experience in solar pumping systems, Solartech recommends customers to add a reactor in such conditions, which is installed at the output side of solar pumping inverter. The reactor is used to reduce the output voltage gradient and minimize the disturbance and shock to motor winding, in order to ensure the motor’s long term stable operation.

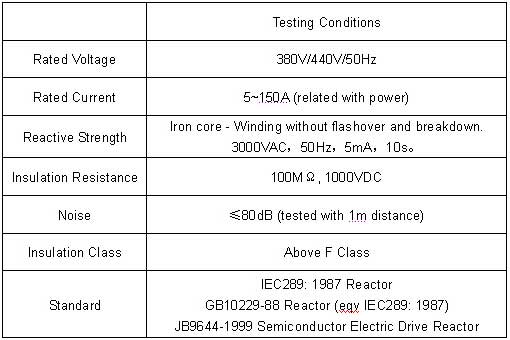

The selection of reactor includes the rated AC current selection, the impedance drop selection, inductance value selection etc. Electrical specifications as below.

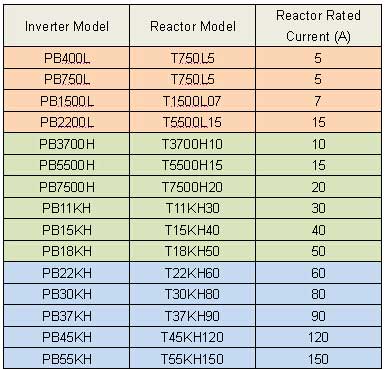

The matching list of Solartech solar pumping inverters and reactors as below

Written by Solartech Technology Engineering Center